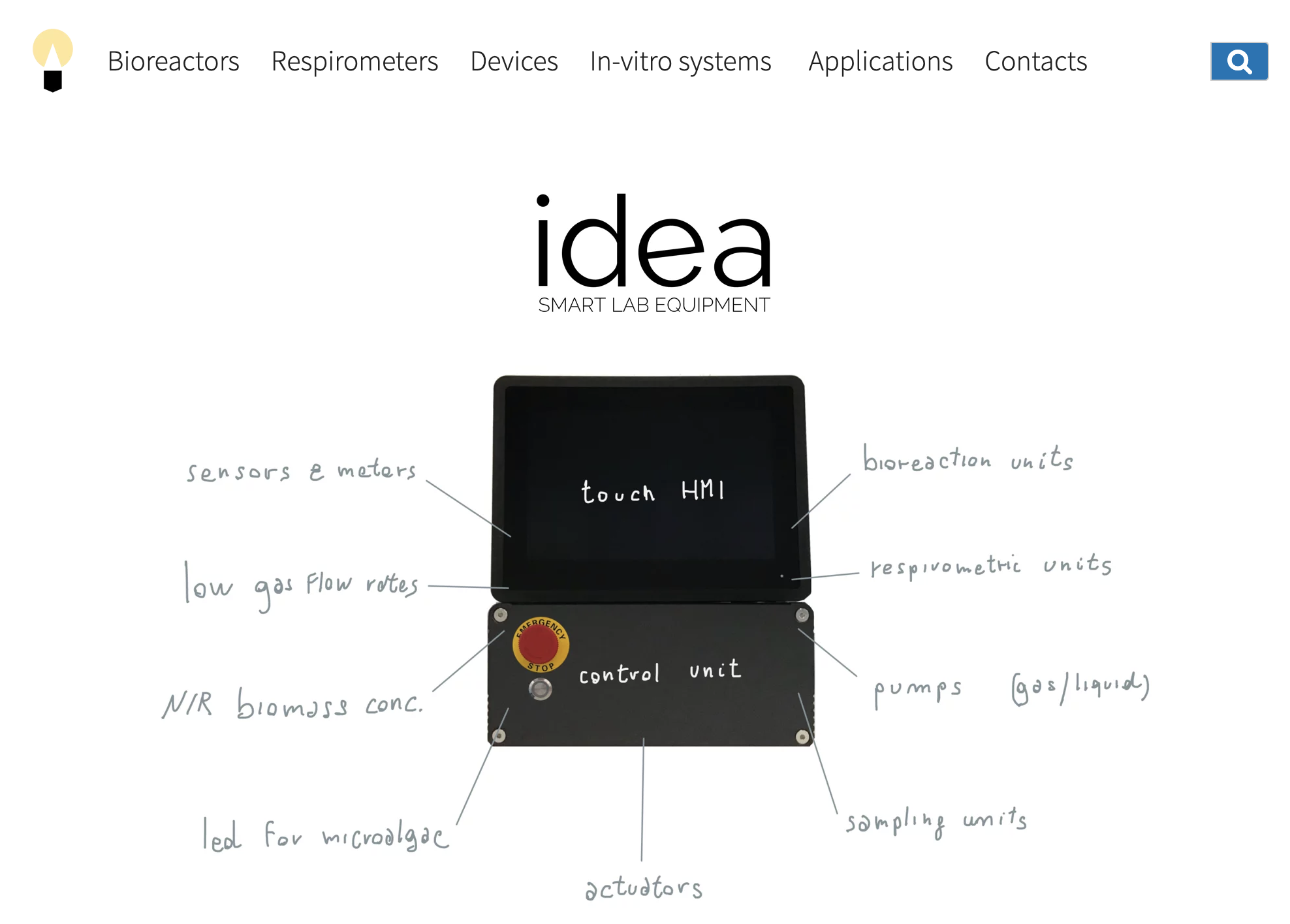

IDEA’s one-task devices are the essence of our modular technology performing several tasks such as

stirring/mixing, sensor integration, gas/liquid handling, pumping, light control for photo-bioreactors, temperature control. Some devices can be “stand-alone” whereas others need to be integrated into an equipment (at least one Industrial Grade PC, IGPC). Just click on the device and see what task can perform.

Do you need more information?

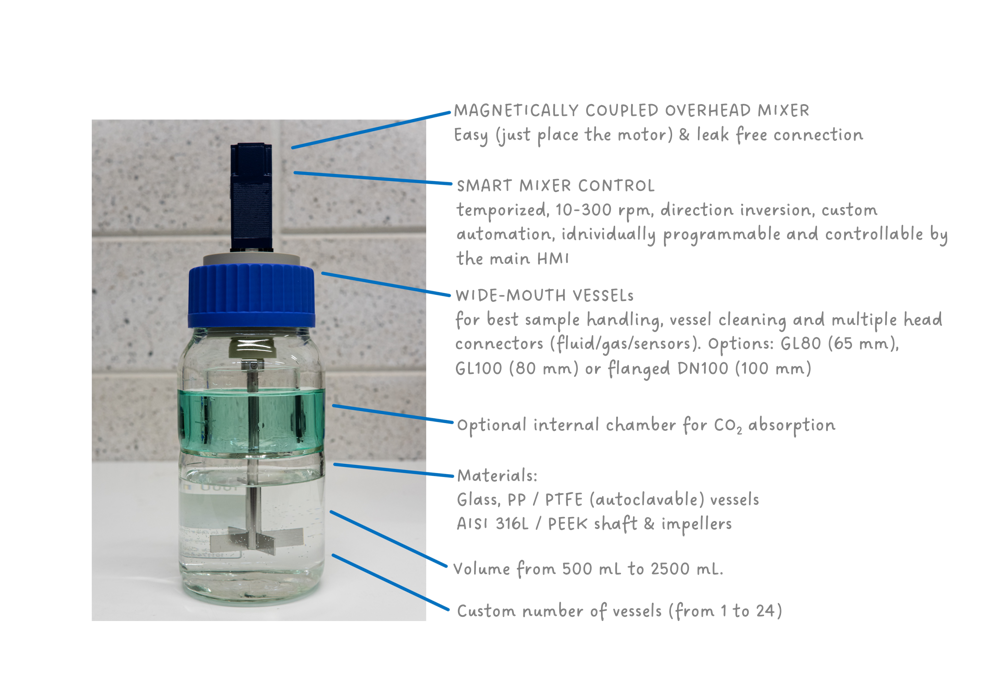

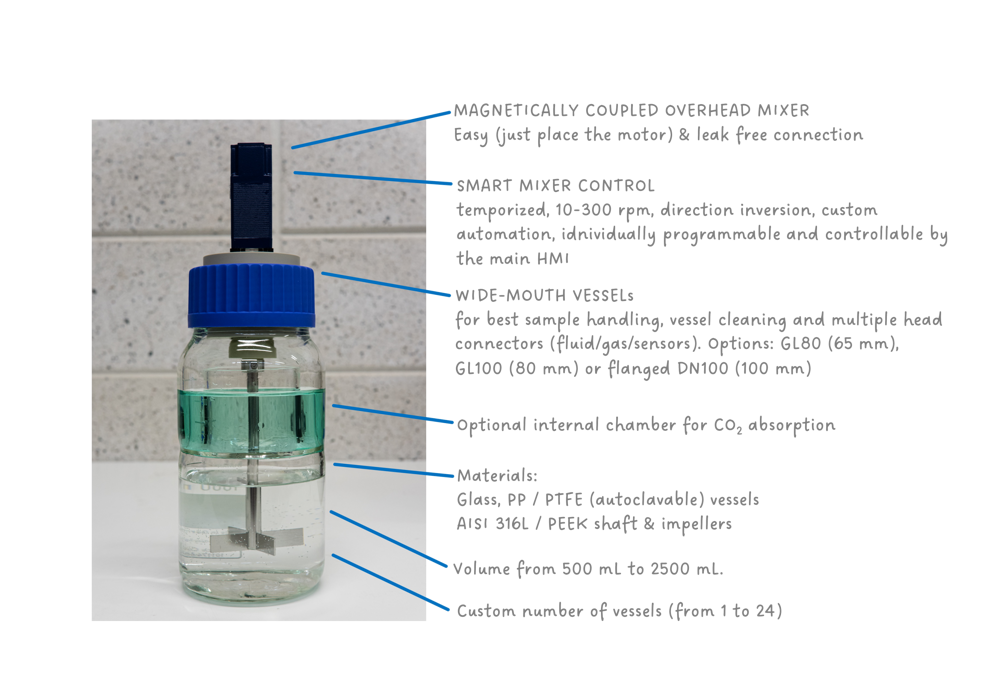

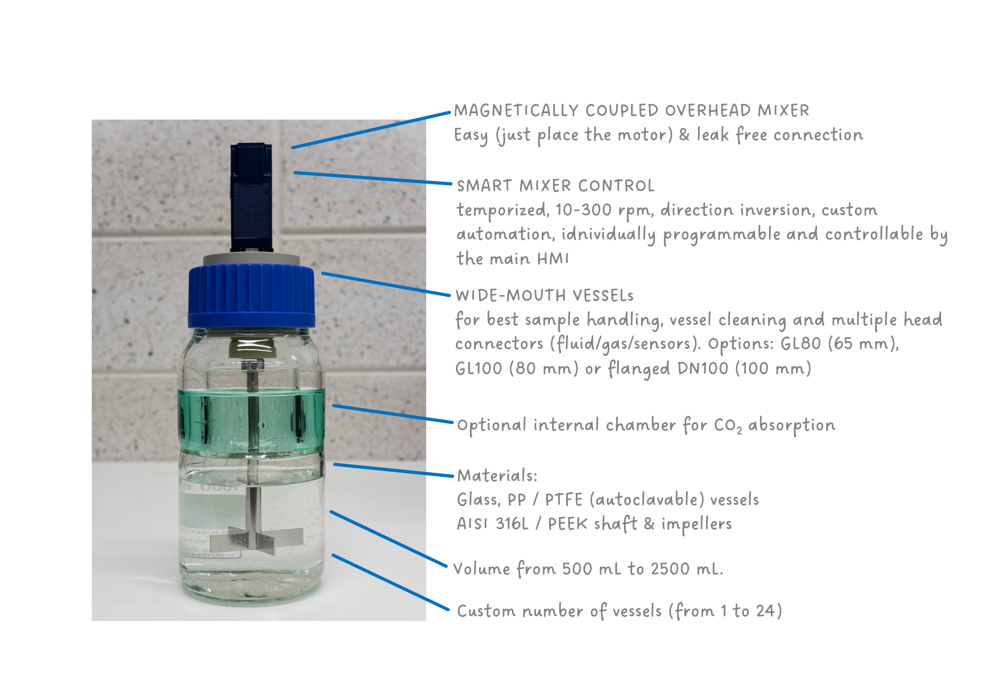

Respirometer features 1 - The vessel

Latest News

Company

Download

Download

New website !!!

Admin

2025-08-07 11:35

2025-08-07 11:35

New website is coming...

Admin

2025-07-01 11:22

2025-07-01 11:22

AlgaEurope 2022

Admin

2022-11-29 14:57

2022-11-29 14:57

Deletion of user data and Google Analytics

Admin

2022-07-07 12:03

2022-07-07 12:03

EUBCE 2020

Admin

2020-07-13 12:04

2020-07-13 12:04

IWAlgae 2019

Admin

2019-07-04 17:01

2019-07-04 17:01

New Website

Admin

2018-10-10 10:30

2018-10-10 10:30

Lab Control and Automation

Address

IDEA BIOPROCESS TECHNOLOGY srls

via A. Locatelli 63

24121 Bergamo (BG)

Italy

Contact

info@idea-biotech.com

Products

Legal

Lab Fluid Control

We provide several solutions for handling gas/liquid fluids in lab biotechnology applications, from simple operations such as open/close control of solenoid valves / pinch valves and on/off switching of air pumps, measuring of gas flow originated from bioreactors, measuring and controlling flowrates of gases fed to bioreactors (analogic rotameters, digital mass flow meters/controller) and controlling variable rpm air/liquid pumps, SMART pumps (intelligent peristaltic pump from 100 microL/min to 6 L/min for dosing/controlling needs), micro-liter dosing pumps, automatic syringe pumps and automatic pipettes.

Copyrights © 2025 - All rights reserved - IDEA BIOPROCESS TECHNOLOGY SRLS - ITALY - VAT: IT04129390169 - FISCAL CODE: 04129390169

Lab automatic sampling devices

We provide automatic sampling machines for sampling from 1 to 8 parallel processes with up to 24 samples per line.

Peristaltic pumps or pinch valves (where a flow is already present) are switched ON to fill sample bottles according to specific time intervals or on the basis of sensor signals.

After the sampling step the lines are empted in order to avoid any contamination between two consecutive samples.

The lines can be washed and sterilized.

Automatic testing devices

The automatic testing device has been introduced to automate O2 respirometric tests in order to perform cyclic testing on a single process (1 point) or to test max 6 samples (n points) automatically*.

Any test cycle consists of 4 steps:

1) Sampling (left channel of 3 way pinch valve + clockwise pumping)

2) Test & Reaction

3) Empting the vessel (right channel of 3 way pinch valve + counterclockwise pumping)

4) Water & Air cleaning and empting

*individual pinch valves are activated to pump one sample at a time.

Interested in lab automation?